Benefits of working with us

The dismantling of floors is a complex and responsible task. Our company "Demontazhnik" has more than 20 years of successful experience in the dismantling of concrete and reinforced concrete floors of various designs (monolithic, slab, precast-monolithic). We offer our clients impeccable quality of work and professionalism at every stage of the project.

The dismantling of floors is a complex and responsible task. Our company "Demontazhnik" has more than 20 years of successful experience in the dismantling of concrete and reinforced concrete floors of various designs (monolithic, slab, precast-monolithic). We offer our clients impeccable quality of work and professionalism at every stage of the project.

Experienced specialists make a preliminary calculation of the cost of dismantling the floor, taking into account various factors, such as the type of floor, the presence of communications, the complexity of the design, the possibility of using special equipment, and so on. This approach allows our clients to accurately plan the budget and avoid unexpected costs.

Our fleet of modern equipment and machinery ensures efficient and safe dismantling of ceilings of any complexity. We pay attention to detail and adhere to high safety standards to minimize risk and ensure project success. In addition, our team of experts is always available to provide professional advice and guidance to help customers optimize the demolition process and achieve the best results.

We are ready to perform the full range of works on the dismantling of ceilings - dismantling, removal and disposal of construction waste or its processing for reuse.

Dismantling of ceilings of various types

- Ceilings from concrete slabs. First, the cement screed is removed, then a strobe about 30 cm long is cut, after which individual sections of cement are knocked down with a chipper. The location of the reinforcement in the slab and its direction are determined. The slab is destroyed along the reinforcing bars in strips up to 40 cm wide. For this, a jackhammer is often used, and a gas cutter is used to cut the reinforcing bars. The last step will be the dismantling of the supporting beams, starting with the auxiliary, then the main ones.

- Concrete vaults. For their dismantling, transverse or longitudinal methods are used. In the first case, the vault is destroyed in parts, no longer than 2 meters. In the second case, spacers from a beam with a diameter of 18 cm are used, placed every 3 meters, in order to unload the adjacent vaults.

- Monolithic ceilings. The dismantling of monolithic floors is carried out using an approach similar to the dismantling of concrete slabs. First, the direction of the reinforcement is determined, after which the overlap is broken along the rods in strips 30-40 cm wide.

- Wooden floors. First remove the backfill, floorboards and running boards, using a nail puller or crowbar to separate the boards from the beams. The ceiling lining is removed in the same way. The beams are removed, and then they are supported from the sides, for easier sawing. This method is considered relatively simple and can be done on your own.

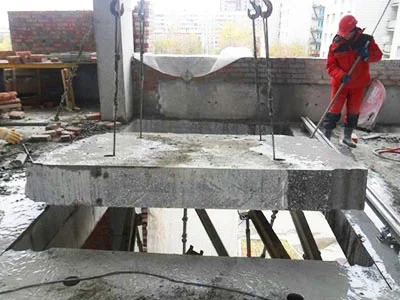

The process of dismantling concrete floors

An important aspect when dismantling ceilings is to ensure maximum safety and the correct execution of each step. First of all, you need to make sure that access to the place of work by unauthorized persons is completely restricted. Inspection of the object and drawing up a detailed plan of upcoming actions become the initial stages.

An important aspect when dismantling ceilings is to ensure maximum safety and the correct execution of each step. First of all, you need to make sure that access to the place of work by unauthorized persons is completely restricted. Inspection of the object and drawing up a detailed plan of upcoming actions become the initial stages.

An important step is to obtain the appropriate permits, which allow for dismantling. Also, before starting dismantling, it is necessary to turn off all communications, while ensuring the protection of existing wires and networks.

The procedure for dismantling floors includes the following steps:

- Destruction of the main concrete slabs using a variety of methods such as diamond cutting, breaking with impact equipment and machinery, etc.

- This is followed by the destruction of reinforcement, adhering to technological norms and rules.

- All elements are eliminated while maintaining the structural integrity of the object, while guaranteeing safety.

- The last stage includes a thorough cleaning of the working area and the subsequent removal of the resulting construction debris.

Proper organization of dismantling works, as well as strict adherence to procedures, ensures the safety and efficiency of the entire dismantling process.

Features of the dismantling of concrete floors

The process of dismantling concrete floors is subject to certain rules, it is important to remember which. Before starting the main work, it is necessary to carry out the preparatory stages: turning off all communications (electrical, plumbing, plumbing), removing floor coverings, fencing the floor or level below what will be dismantled, as well as preparing a place for dumping parts of the structure.

It is important to follow the sequence of actions, and not allow the simultaneous dismantling of the ceiling at different levels. In the case of working with a multi-storey building, you should first prepare a crane (winch) to remove the disassembled parts of the partition or ceiling.

Slabs dismantling

The dismantling of slabs is a process that requires careful planning and a professional approach. Regardless of the type of structure, be it reinforced concrete, monolithic or concrete slabs, quality demolition plays a key role in ensuring safety and efficiency.

The dismantling of reinforced concrete slabs is a complex task requiring high competence. Considering a variety of factors, including dimensions, reinforcement and layout, professionals develop a strategy for effectively deconstructing a structure.

When dismantling a monolithic slab, it is especially important to take into account the structural characteristics. Specialists choose the best methods and tools, ensuring safe destruction and minimizing the impact on the surrounding elements.

The process of dismantling a concrete slab requires precise coordination. From site preparation and selection of the right equipment to cost and safety considerations, every detail matters.

The price of dismantling concrete slabs depends on many factors, such as the scope of work, the complexity of the structure, the availability of the site, and the methods chosen. Our professional team evaluates these aspects in order to provide our customers with competitive prices while maintaining a high standard of quality.

The preliminary calculation of the price of dismantling floors is made on the basis of the following data:

The preliminary calculation of the price of dismantling floors is made on the basis of the following data:

The dismantling of floors is a complex and responsible task. Our company "Demontazhnik" has more than 20 years of successful experience in the dismantling of concrete and reinforced concrete floors of various designs (monolithic, slab, precast-monolithic). We offer our clients impeccable quality of work and professionalism at every stage of the project.

The dismantling of floors is a complex and responsible task. Our company "Demontazhnik" has more than 20 years of successful experience in the dismantling of concrete and reinforced concrete floors of various designs (monolithic, slab, precast-monolithic). We offer our clients impeccable quality of work and professionalism at every stage of the project. An important aspect when dismantling ceilings is to ensure maximum safety and the correct execution of each step. First of all, you need to make sure that access to the place of work by unauthorized persons is completely restricted. Inspection of the object and drawing up a detailed plan of upcoming actions become the initial stages.

An important aspect when dismantling ceilings is to ensure maximum safety and the correct execution of each step. First of all, you need to make sure that access to the place of work by unauthorized persons is completely restricted. Inspection of the object and drawing up a detailed plan of upcoming actions become the initial stages.